Jiangsu Young-Will Aerospace Equipment Technology Co., Ltd. is located in Taicang, Jiangsu. It focuses on providing precision component design optimization and product manufacturing services based on metal additive manufacturing technology for commercial rockets and commercial satellites. It is currently one of the manufacturers with the most successfully launched commercial aerospace additive components in China.

Looking up at the founding team of Aerospace, which has been deeply involved in the field of metal material forming for many years, The company has over 80 employees. The team has broken through technical barriers such as lightweight and integrated structural design, and has the advantages of higher safety, better performance, and lower manufacturing costs. It has achieved the installation and application of core components of rocket engines, satellite electric propulsion storage and control modules, gas cylinders, and other products. Based on the company's focus on the commercial aerospace field, compared with its competitors, it has significant advantages in both product price and delivery cycle while ensuring product quality, especially for mass-produced components.

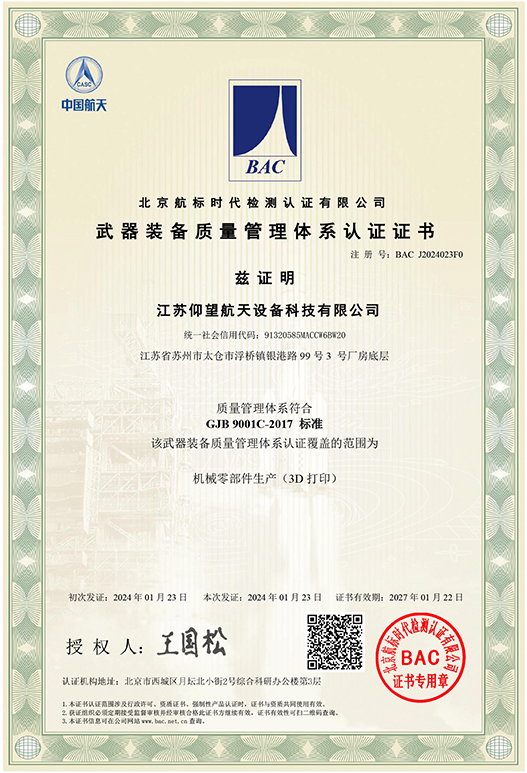

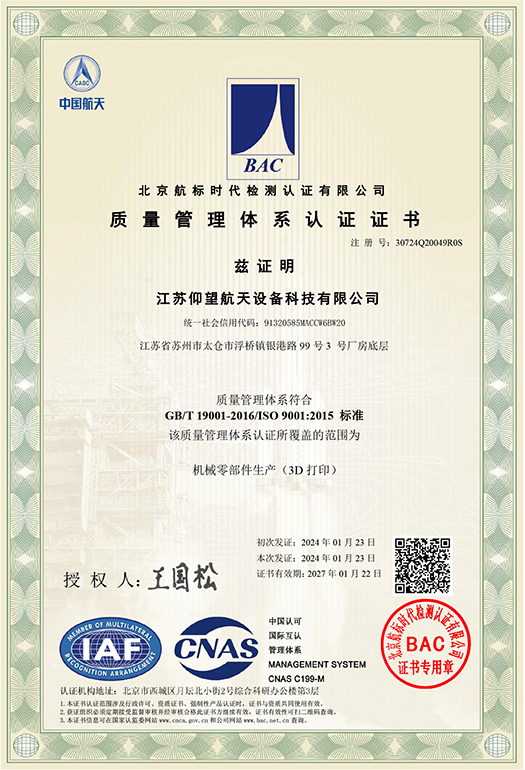

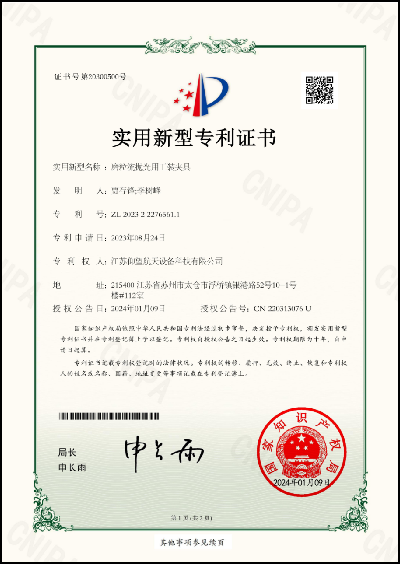

The company has been awarded the title of Technology Leading Enterprise in Taicang City, and its founder is the "Gusu Talent" of Suzhou City, a leading talent in innovation and entrepreneurship. The company has obtained quality management system ISO9001 (GB/T19001), weapon and equipment quality management system GJB9001C, environmental management system GB/T 24001-2016/ISO 14001:2015, etc. In terms of intellectual property, the company currently holds 18 patents (including those under review) and 2 software works. As a member unit of the Special Processing Association, the company has participated in drafting and formulating multiple national and enterprise standards for metal additive manufacturing.

Our core products are mainly based on metal additive manufacturing technology, widely used in the following fields:

Commercial aerospace rocket field: including attitude and orbit control engine body, nozzle extension section, and assembly block; Liquid rocket engine thrust chamber, turbopump, valves, final assembly structure, pipelines, etc;

Commercial aerospace satellite field: including different types of electric propulsion storage and control modules, satellite antennas, signal interconnection devices, satellite brackets, etc;

In the field of thermal control, it includes accompanying channel liquid cooled shells, lattice structure phase change cooling plates, air-cooled radiator cores, complex structure radiators, etc.

The clients served include Aerospace Science and Technology Fifth Institute, Aerospace Science and Technology Eleventh Institute, Blue Arrow Aerospace, Star River Power, Star Glory, etc.

At present, mainstream metal materials including aluminum alloy, stainless steel, high-temperature alloy, titanium alloy, copper alloy, etc. can be printed. The company has advanced metal 3D printing equipment of various models, and the production department has a comprehensive production management plan. At the same time, the quality department has the corresponding quality testing capabilities required for metal additive manufacturing to ensure product quality and delivery time.