Industrial applications

Design optimization

Various biomimetic structures are used to design internal cavity spaces (such as TPMS) and simulate and test them to optimize product structures.

Improved heat dissipation capability

Utilizing metal additive manufacturing to create complex shaped structures, optimizing heat transfer specific surface area and flow resistance.

Output

Completed the transition from testing and validation to mass production, reducing costs.

Typical products for industrial applications

-

- Product Name: Copper Electrode

- Printing time:

- Printing process:

- Application areas:

- texture of material:

- Printing equipment:

- Product size:

-

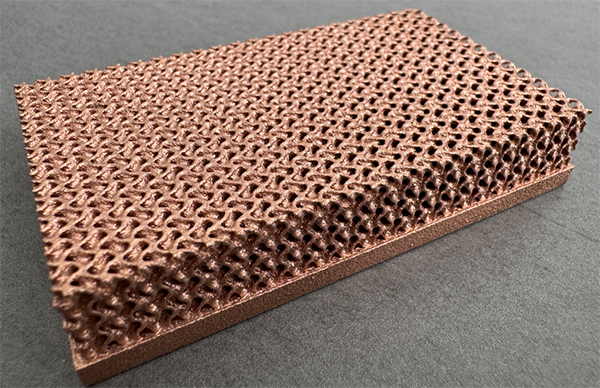

- Product Name: Thermal TPMS Structure

- Printing time:

- Printing process:

- Application areas:

- texture of material:

- Printing equipment:

- Product size:

-

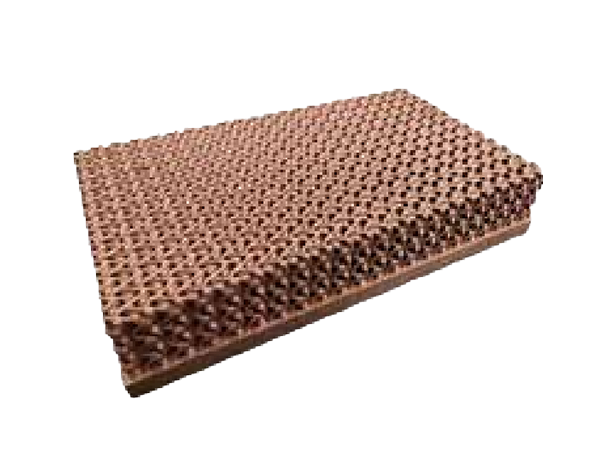

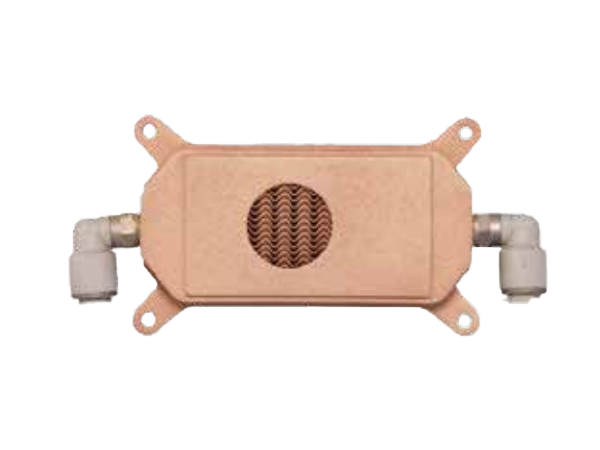

- Product Name: Liquid Cooling Heat Dissipation

- Printing time:

- Printing process:

- Application areas:

- texture of material:

- Printing equipment:

- Product size:

-

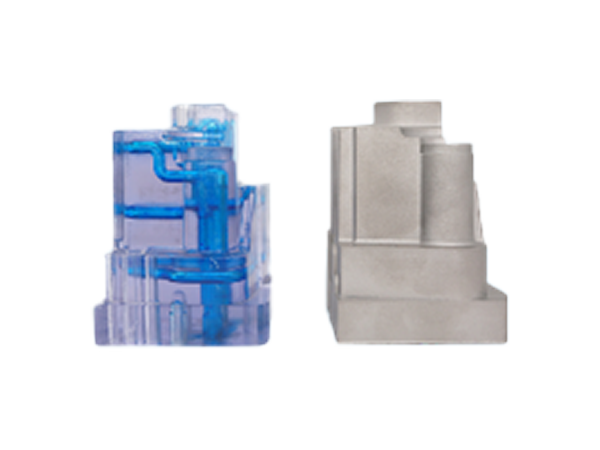

- Product Name: Bearing Pipe Valve

- Printing time:

- Printing process:

- Application areas:

- texture of material:

- Printing equipment:

- Product size:

-

- Product Name: Random waterway mold

- Printing time: 4.6 hours

- Printing process: laser selective melting

- Application area: Model

- Material: Mold steel

- Printing equipment: M260

- Product size: Ø 47X65mm ³

-

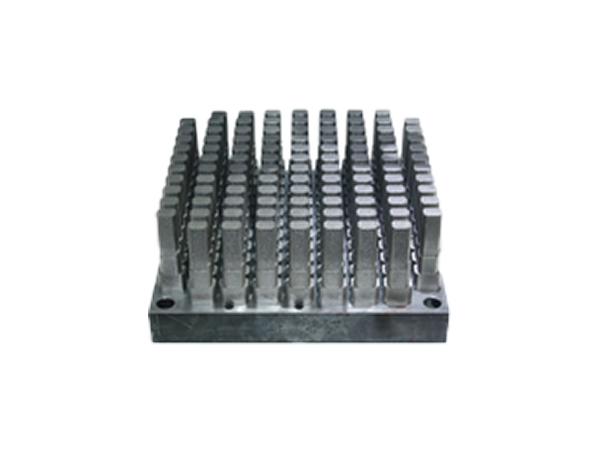

- Product Name: Mold

- Printing time: 5 hours

- Printing process: laser selective melting

- Application area: Model

- Material: Mold steel

- Printing equipment: M260

- Product size: Ø 70X60mm ³

-

- Product Name: Random waterway mold

- Printing time: 12 hours

- Printing process: laser selective melting

- Application area: Model

- Material: Mold steel

- Printing equipment: M260

- Product size: 80X80X110mm ³

-

- Product Name: Tire Mold

- Printing time: 42 hours

- Printing process: laser selective melting

- Application area: Model

- Material: Mold steel

- Printing equipment: M260

- Product size: 225X200X35mm ³

-

- Product Name: Shoe Model

- Printing time: 30 hours

- Printing process: laser selective melting

- Application area: Model

- Material: Mold steel

- Printing equipment: M300

- Product size: 350X135X55mm ³

-

- Product Name: Electronic Cigarette Mold

- Printing time: 78 hours

- Printing process: laser selective melting

- Application area: Model

- Material: Mold steel

- Printing equipment: M260

- Product size: 25X15X75mm ³ (individual)