Aviation applications

Integrated Integration

Save space and achieve integration within strict aviation product design constraints.

Internal channel polishing

We have independently developed internal channel polishing technology and formulated a reasonable process according to usage requirements to meet the internal smoothness and flow resistance of complex channels.

Ultimate weight loss

Ensure minimum weight to meet strict payload limitations.

Typical products for aviation applications

-

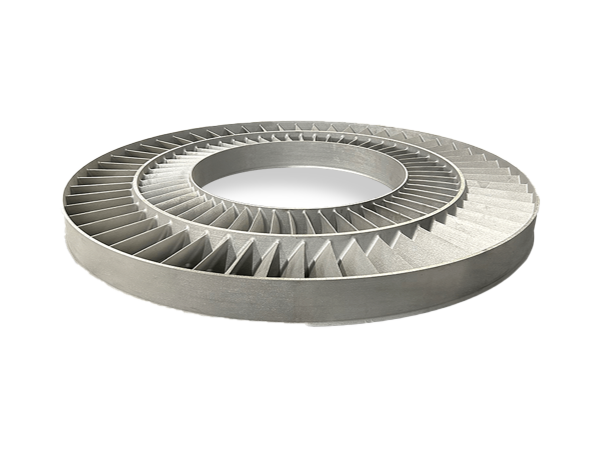

- Product Name: Impeller

- Printing time: 140 hours

- Printing process:

- Application field: Aerospace

- Material: 316L

- Printing equipment: M1550

- Product size: Ø 1400X105mm ³

-

- Product Name: Multi dimensional connector

- Printing time: 32 hours

- Printing process: laser selective melting

- Application field: Aerospace

- Material: 30crmosi

- Printing equipment: M260

- Product size: 105X90X200mm ³

-

- Product Name: Wind Speed Tube

- Printing time: 34 hours

- Printing process: laser selective melting

- Application field: Aerospace

- Material: Nickel

- Printing equipment: M260

- Product size: 235X40X75mm ³

-

- Product Name: Cabin Section

- Printing time: 86 hours

- Printing process: laser selective melting

- Application field: Aerospace

- Material: Aluminum alloy

- Printing device: M450

- Product size: Ø 340X470mm ³

-

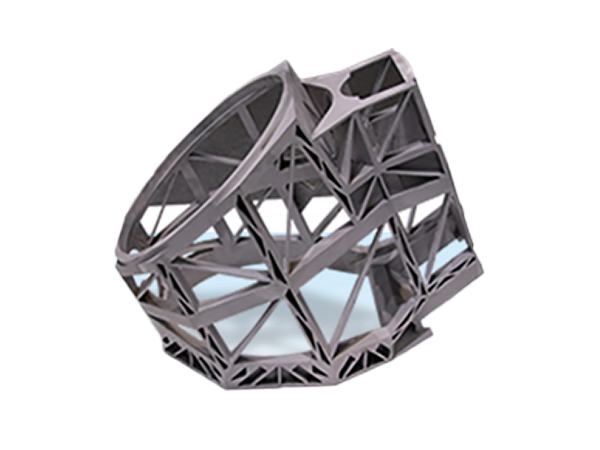

- Product Name: Framework

- Printing time: 176 hours

- Printing process: laser selective melting

- Application field: Aerospace

- Material: Aluminum alloy

- Printing equipment: M650

- Product size: 470X400X499mm ³

-

- Product Name: Oil and Gas Nozzle

- Printing time: 384 hours

- Printing process: laser selective melting

- Application field: Aerospace

- Material: IN718 high-temperature nickel based alloy

- Printing equipment: M450H

- Product size: Ø 420X870mm ³

-

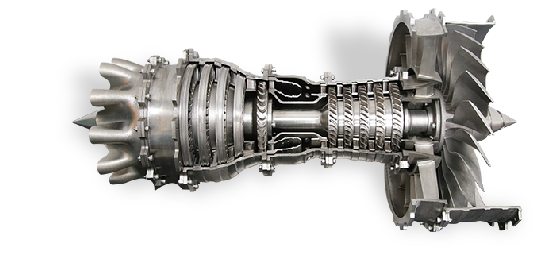

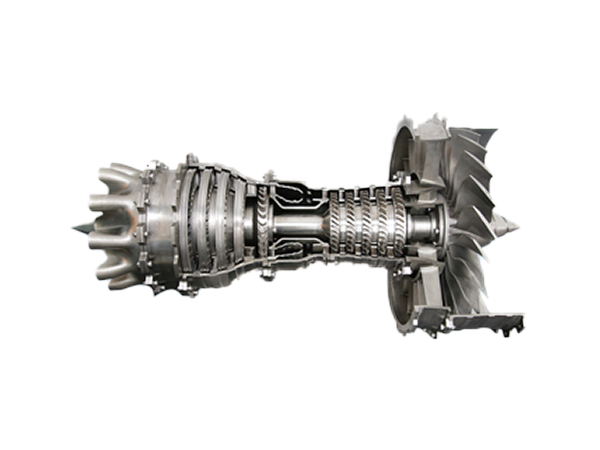

- Product Name: Aircraft Engine

- Printing time: 580 hours

- Printing process: laser selective melting

- Application field: Aerospace

- Material: IN718 high-temperature nickel based alloy

- Printing equipment: M650

- Product size: 860X420X480mm ³

-

- Product Name: Engine Expansion Segment

- Printing time: 173 hours

- Printing process: laser selective melting

- Application field: Aerospace

- Material: 316L

- Printing equipment: M650H

- Product size: 630X630X1100mm ³