Solution - Integrated and Lightweight

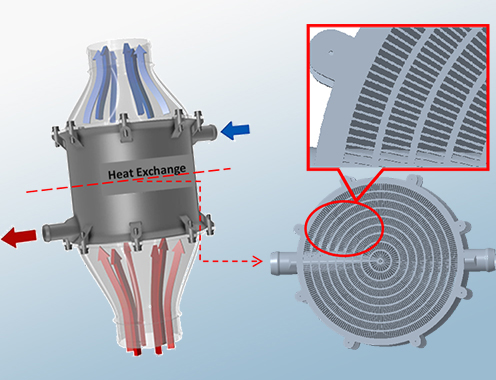

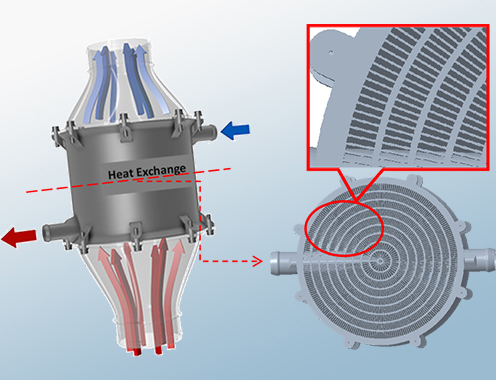

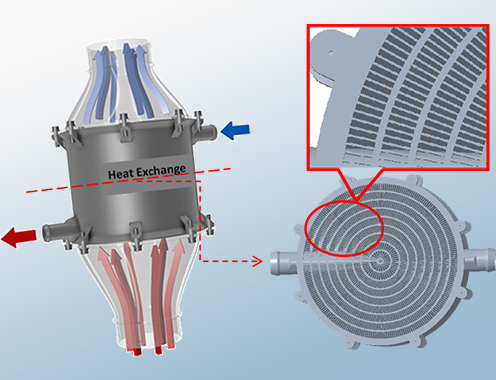

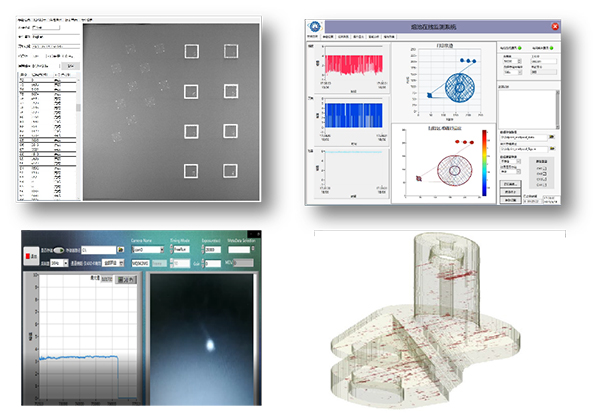

Structural optimization design (radiator, regenerative cooling structure thrust chamber, etc.)

● Determine optimization objectives such as maximum stiffness, minimum mass, or minimum volume based on known design space

● By calculating the optimal force transmission path within the material and optimizing the unit density to determine the materials that can be excavated, the optimal material distribution within the structural setting area can be obtained

● Design and optimize the structure of parts through 3D software and finite element software, and independently design hollow lattice, honeycomb or microchannel structures

● Achieve a structural weight reduction of over 40% and a heat dissipation efficiency improvement of over 50%

● The optimized design of the structure greatly improves the stability of the product compared to traditional welding methods