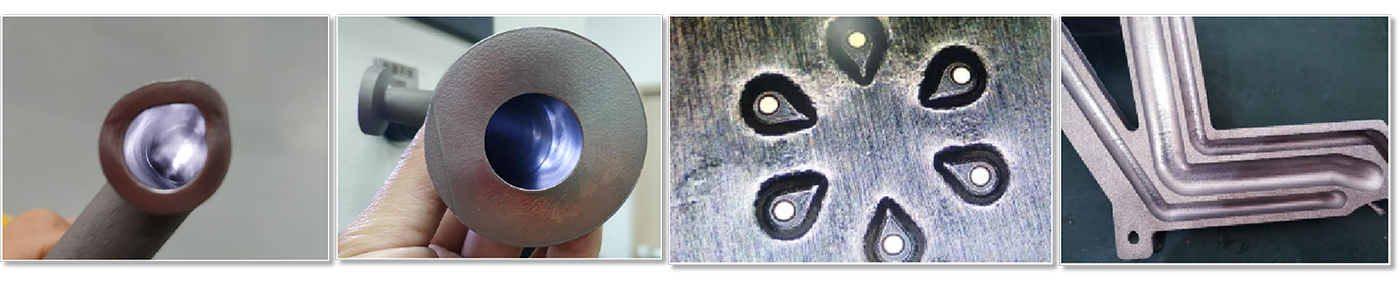

High pressure self-developed abrasive inner channel polishing process (patent number: 2023222765611) (Ra<0.8 μ m)

Using high-pressure extrusion special SiC abrasive, the SiC abrasive grinding mechanism generates shear force on the surface of the flow channel, causing it to pass through the inner cavity or surface of the part, forming friction grinding, thereby removing foreign objects and burrs.

Technical advantages

It is widely used in products with complex microchannels such as rocket liquid engine thrust chamber body and electric propulsion storage control module, which belong to the core process technology of the product

(1) Solved the problem of easy blockage and residue during polishing of microchannels

(2) Solved the problem of surface finishing inside microchannels

(3) Achieved polishing effect on the inner surface of complex microchannels

| Material grade that can be processed | Aluminum alloy, titanium alloy, high-temperature alloy, stainless steel |

|---|---|

| Specially made abrasives mixed into the fluid | About 1%~3% |

| Grinding accuracy of inner channel | 0.45±0.01mm |

-

- Equipment Name: Fluid Polishing Machine

- Maximum working width: 400mm

- Maximum working height: 300mm

- Abrasive cylinder capacity: 8L

- Abrasive cylinder pressure: 250~1450psi

- Number of units in stock: 2 units

- Applicable products: Rocket engine valves, bent pipes and other products;

-

- Equipment Name: Fluid Polishing Machine

- Maximum working width: 350mm

- Maximum working height: 225mm

- Abrasive cylinder capacity: 3L

- Abrasive cylinder pressure: 250~1450psi

- Number of units in stock: 4 units

- Applicable products: Satellite electric propulsion storage control module and other products

-

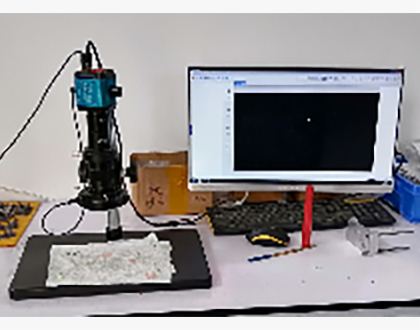

- Equipment Name: Electron Microscope

- Number of units in stock: 2 units

- Purpose: Appearance inspection