Testing - Testing Capability

-

X-ray digital imaging system

The company has its own digital X-ray imaging system, which can detect internal defects and excess material in the internal flow channel to ensure product quality. Relying on X A digital technology platform for non-destructive testing of X-ray transmission imaging samples, used for characterizing the internal structure of metal additive manufacturing products. Combining analysis software to achieve imaging of internal structures and applying it to the characterization of sample specimens is an effective means for product research, failure analysis, highly reliable screening, quality evaluation, and process improvement.

Equipment Name: Universal Digital X-ray Digital Imaging System Maximum voltage: 450kV

Maximum detection size: 800mm (diameter) × 1000mm (height)

Effective area: 410 × 410mm

Pixel size: 200um

Pixel count: 2048 × 2048

Applicable products: Metal additive manufacturing products for rocket engine components, satellite components, industrial heat dissipation and other fields -

3D contour scanning

Handheld laser 3D scanner uses multiple laser line grids to project onto the surface of an object, collects data through high-speed and high-resolution industrial cameras, calculates the 3D point cloud of the object through 3D scanning software, and obtains the 3D data of the object. Scanning is free and flexible, and the entire process is completed handheld without the need for a tripod or other support device. Adopting motion prediction anti shake algorithm to avoid the impact of human shaking on scanning accuracy during the scanning process. For difficult to measure dimensions such as curved surfaces, a dimensional deviation cloud map is formed by comparing the 3D contour scan with the original numerical model to confirm the overall dimensional accuracy of the product.

Device Name: Handheld Laser 3D Scanner

Maximum detection size: unlimited

Applicable products: Metal additive manufacturing products for rocket engine components, satellite components, industrial heat dissipation and other fields

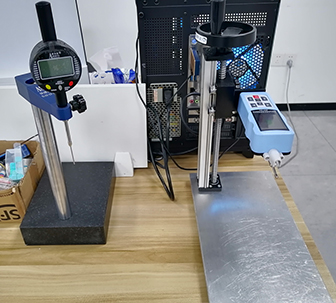

Roughness meter, etc

-

Capable of routine roughness detection

Equipment Name: Roughness Tester

Application products: various products

Anime projector

-

Capable of conventional form and position tolerance detection

Equipment Name: Roughness Tester

Application products: various products -

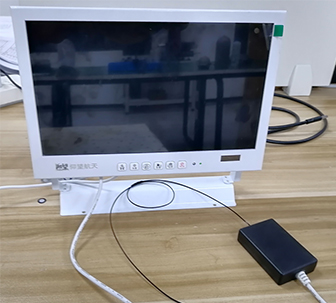

1.2mm endoscope

-

For products with small internal flow channel structures, practical endoscopes provide a more intuitive observation of the internal flow channel smoothness and excess material, ensuring the quality of the internal flow channel.

Equipment Name: Endoscope Main specifications: φ 1.2mm (probe)

Application products: Satellite electric propulsion storage and control module, attitude and orbit control engine thrust chamber, etc. -

ultrasonic thickness gauge

-

Capable of conventional thickness detection

Equipment Name: Ultrasonic Thickness Gauge Application products: various products -

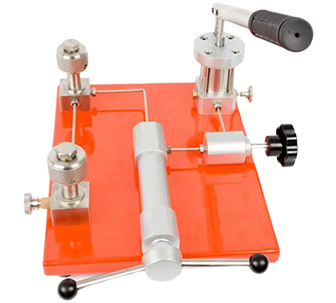

Hydraulic airtightness testing

-

Capable of hydraulic testing.

Equipment Name: Endoscope Equipment Name: Hydraulic Testing

Specification: 0~60Mpa

Application: Phase change energy storage shell -

Hydraulic airtightness testing

-

Capable of conducting airtight testing.

Equipment Name: Hydraulic Testing

Specification: 0~10Mpa

Application: Phase change energy storage shell, etc. -

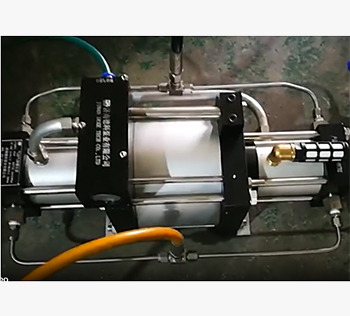

Hydraulic testing platform

-

Capable of hydraulic testing.

Equipment Name: Hydraulic Testing Platform

Specification: 0~100Mpa

Application: Attitude and orbit control engine, phase change energy storage housing, etc. -

Airtight testing platform

-

Capable of conducting airtight testing.

Equipment Name: Airtightness Testing Platform

Specification: 0~35Mpa

Application: Attitude and orbit control engine, phase change energy storage housing, etc. -

Flow resistance detection table

-

Capable of detecting flow resistance.

Equipment Name: Flow Resistance Detection Platform

Specification: 120kg/s

Application: Attitude and orbit control engine, phase change energy storage housing, etc.